close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-10-07 Origin: Site

The global manufacturing landscape is going through a significant transformation. Industries are moving away from traditional production methods toward advanced manufacturing, which emphasizes precision, efficiency, sustainability, and high-performance materials. At the heart of this shift lies a group of lesser-known but extremely valuable compounds: rare earth sulfates.

Although rare earth sulfates are not as well-known as metals like steel, copper, or aluminum, they are quietly driving innovation in sectors such as clean energy, electronics, automotive, aerospace, and advanced materials. Their unique properties, versatility, and ability to enable high-tech applications make them indispensable for the future of modern industry.

This article explores in detail how rare earth sulfates support the transition to advanced manufacturing, their key applications, economic and environmental aspects, and what their growing importance means for global industries.

Rare earth sulfates are compounds formed when rare earth elements combine with sulfate ions. The rare earth elements include lanthanides such as cerium, lanthanum, neodymium, praseodymium, and yttrium. These elements are often grouped together because they share similar chemical properties, even though their individual characteristics vary.

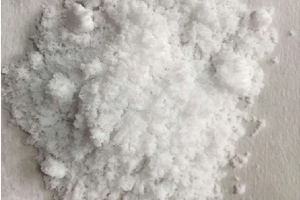

Rare earth sulfates typically appear as crystalline solids or powders and are usually produced during the processing of rare earth ores. In many cases, they are intermediate products, later converted into other useful forms such as oxides, fluorides, or metals. However, even in sulfate form, they are highly valuable and directly used in several advanced applications.

What makes rare earth sulfates important is their combination of:

Thermal stability, allowing use in high-temperature environments

Catalytic activity, enabling faster and more efficient chemical reactions

Magnetic and electronic properties, essential for energy storage and electronics

Versatility, as they can be processed into different rare earth derivatives

Because of these attributes, rare earth sulfates are often considered “gateway materials” that connect natural resources to cutting-edge applications.

Advanced manufacturing refers to production methods that integrate innovative technologies such as automation, robotics, artificial intelligence, and high-performance materials. Unlike conventional manufacturing, which focuses on mass output, advanced manufacturing emphasizes efficiency, sustainability, and customization.

Rare earth sulfates play a crucial role in this transition because they enable the materials and components required for modern technology. For example, they are used in catalysts for cleaner industrial processes, in magnets for electric vehicles, and in materials for electronics and optics. Without rare earth sulfates and the elements they provide, many advanced manufacturing processes would struggle to meet performance or sustainability goals.

One of the most important uses of rare earth sulfates is in catalysis. Catalysts are substances that speed up chemical reactions without being consumed in the process. Rare earth sulfates, particularly cerium and lanthanum sulfates, are widely used to produce catalysts for oil refining, petrochemical processes, and emission control systems.

In petroleum refining, rare earth sulfates help improve fluid catalytic cracking (FCC), which breaks down heavy crude oil into lighter, more valuable fuels like gasoline and diesel. These catalysts not only enhance efficiency but also reduce unwanted by-products.

In environmental technologies, rare earth sulfates are key to catalytic converters in vehicles, where they help reduce harmful emissions such as carbon monoxide and nitrogen oxides. By supporting cleaner industrial processes and transportation systems, rare earth sulfates directly contribute to sustainability goals in advanced manufacturing.

The transition to renewable energy and electric mobility requires efficient energy storage. Rare earth sulfates support this demand by serving as precursors for materials used in rechargeable batteries. For instance, lanthanum and cerium compounds derived from sulfates are used in nickel-metal hydride (NiMH) batteries, which power hybrid vehicles and some industrial applications.

As research into advanced batteries continues, rare earth sulfates may also play a role in next-generation energy storage systems, providing stability, improved charge cycles, and higher energy densities. These capabilities are essential for advanced manufacturing sectors that depend on reliable and sustainable energy sources.

Another critical use of rare earth sulfates is in the production of rare earth metals and oxides that form permanent magnets. Neodymium, praseodymium, and dysprosium—elements often derived from sulfates—are essential for creating neodymium-iron-boron (NdFeB) magnets. These magnets are among the strongest in the world and are indispensable in electric motors for electric vehicles, wind turbines, and robotics.

As industries adopt automation and electrification, the demand for powerful and compact magnets continues to grow. Rare earth sulfates ensure the supply of the necessary materials, directly linking them to the future of clean transportation and renewable energy generation.

Rare earth sulfates are also used in the production of advanced glass and ceramics. They provide properties such as improved durability, UV resistance, and optical clarity. For example, cerium sulfate is used to polish glass surfaces, while lanthanum sulfate contributes to high-quality optical lenses.

In advanced manufacturing, optics are critical for applications like precision instruments, lasers, and communication systems. By supporting the development of these high-performance materials, rare earth sulfates enable industries ranging from healthcare to telecommunications.

In metallurgy, rare earth sulfates are processed into additives that improve the mechanical and thermal properties of metals. They refine grain structures, increase corrosion resistance, and enhance toughness. This makes them valuable in industries like aerospace, where strong yet lightweight materials are essential, and in construction, where durability matters.

Advanced manufacturing relies on such improvements to meet the demands of modern designs that require performance, safety, and efficiency. Rare earth sulfates provide the building blocks for these enhancements.

The value of rare earth sulfates extends beyond their technical applications. They also hold significant economic and strategic importance.

Global demand growth: As advanced manufacturing expands, the demand for rare earth sulfates rises sharply. Clean energy, electric vehicles, and high-tech electronics are all major growth drivers.

Geopolitical considerations: The supply of rare earths, including sulfates, is concentrated in a few countries, with China dominating production. This creates strategic vulnerabilities for other nations dependent on imports.

Industrial competitiveness: Access to rare earth sulfates and the ability to process them effectively are critical for maintaining leadership in high-tech industries. Countries with stable supply chains enjoy a competitive advantage.

Because of these factors, rare earth sulfates are increasingly regarded as strategic materials essential for national security and economic stability.

Despite their importance, the production of rare earth sulfates raises environmental challenges. Mining rare earth ores often involves significant land disruption, chemical use, and waste generation. Sulfate compounds, when not managed properly, can contribute to soil and water contamination.

To address these issues, industries and governments are focusing on:

Recycling: Recovering rare earths from end-of-life products such as electronics, batteries, and magnets reduces the need for primary mining.

Cleaner processing technologies: Innovations are being developed to minimize the environmental footprint of rare earth sulfate production, including closed-loop systems and greener extraction methods.

Regulations and monitoring: Stronger policies ensure safer handling of rare earth sulfates and reduce the risks of contamination.

Sustainability is a core principle of advanced manufacturing, and improving the environmental profile of rare earth sulfate production is essential to align with this principle.

Looking ahead, the role of rare earth sulfates in advanced manufacturing is expected to expand even further. Several trends point to a strong and growing demand:

Electrification of transportation: Electric and hybrid vehicles will drive higher demand for batteries and permanent magnets derived from rare earth sulfates.

Renewable energy expansion: Wind turbines, solar technologies, and energy storage systems rely heavily on rare earth materials.

Advanced electronics: Miniaturized, high-performance electronics and communication devices require specialized optical and magnetic materials.

Sustainable manufacturing: Cleaner industrial processes will continue to depend on rare earth-based catalysts.

As technology evolves, rare earth sulfates will not only remain relevant but become even more central to industrial progress. Their unique properties and versatility make them irreplaceable in many high-performance applications.

Rare earth sulfates may not be widely recognized outside of scientific and industrial circles, but their contribution to advanced manufacturing is profound. From catalysts that enable cleaner processes to compounds that support powerful magnets and efficient energy storage, these materials are shaping the future of industries worldwide.

Their importance is both technical and strategic, linking them to economic competitiveness, national security, and global sustainability goals. While challenges exist in terms of environmental impact and supply concentration, innovation in recycling and processing technologies promises to make rare earth sulfates more sustainable.

As the world transitions toward advanced manufacturing, rare earth sulfates stand as essential enablers—materials that quietly but powerfully support the technologies and industries of tomorrow. Their strategic value ensures that they will remain at the center of industrial development for decades to come.