close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-09-29 Origin: Site

The modern technological world is built upon a foundation of advanced materials. From the magnets in electric vehicles to the catalysts that keep our air clean, and from the alloys in aircraft engines to the screens on our smartphones, rare earth elements are everywhere. Yet, these elements rarely appear in their pure metallic form in nature. Instead, they are extracted, refined, and processed through a series of intermediate compounds. One of the most important of these intermediates is rare earth carbonates.

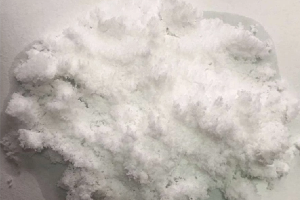

Though they may look like ordinary white or off-white powders, rare earth carbonates play an essential role as the bridge between raw ores and the advanced oxides and alloys that fuel high-tech industries. Without them, the transformation of rare earth resources into usable materials would be far less efficient, limiting the progress of countless technologies.

Rare earth carbonates are salts formed when rare earth elements (the lanthanides, plus scandium and yttrium) combine with carbonate ions (CO₃²⁻). They are usually produced during the processing of rare earth ores, such as bastnäsite, monazite, or laterite clays.

For example:

Bastnäsite ore, one of the main sources of rare earths, naturally contains rare earth fluorocarbonates.

Through chemical processing, rare earth oxides from ores are often converted into carbonates as an intermediate step before further refining.

These carbonates are relatively stable and insoluble in water, which makes them convenient for storage, transport, and controlled processing. Once obtained, they can be transformed into a wide variety of rare earth compounds, including the highly valuable rare earth oxides and alloys.

The significance of rare earth carbonates lies in their role as precursors. They are not usually the final form used in applications but are instead converted into other compounds with tailored properties.

The advantages of rare earth carbonates as precursors include:

Ease of Conversion: They can be readily decomposed into oxides through calcination (heating at high temperatures).

Purification: During carbonate precipitation, impurities can often be removed, ensuring higher purity in the final rare earth products.

Versatility: From carbonates, it is possible to obtain oxides, metals, fluorides, or chlorides, depending on the desired application.

Stability: Unlike some rare earth salts, carbonates are stable and relatively safe to handle, making them practical in large-scale industry.

In short, rare earth carbonates act as the “middlemen” that ensure rare earth elements are processed efficiently and in a form suitable for advanced applications.

One of the most important transformations of rare earth carbonates is into rare earth oxides. Rare earth oxides are the cornerstone of countless technologies, and the process begins with carbonates.

When rare earth carbonates are heated, they undergo thermal decomposition, releasing carbon dioxide gas and leaving behind rare earth oxides. For example:

2RECO3 →heat RE2O3+2CO2↑2 RECO₃ \; \xrightarrow{heat} \; RE₂O₃ + 2 CO₂↑2RECO3heatRE2O3+2CO2↑

where RE represents a rare earth element.

This relatively simple reaction provides oxides with high purity and controlled particle sizes, depending on the processing conditions. These oxides then become essential in:

Catalysts: Cerium oxide for automotive catalytic converters.

Polishing agents: Cerium oxide for glass and semiconductor wafers.

Magnets: Neodymium and praseodymium oxides for high-performance permanent magnets.

Phosphors: Europium and terbium oxides for display and lighting technologies.

Ceramics: Yttrium oxide for high-temperature superconductors and advanced ceramics.

Without rare earth carbonates as the initial precursors, producing such a wide range of high-quality oxides would be far more complicated.

Rare earth carbonates are also important in the production of rare earth alloys. These alloys are used in critical sectors such as aerospace, defense, renewable energy, and electronics.

The typical pathway involves:

Conversion to Oxides: Carbonates are first calcined into oxides.

Conversion to Chlorides or Fluorides: The oxides are then reacted with acids or halides to form rare earth halide salts.

Metal Reduction: These halide salts are reduced using strong reducing agents (like calcium or magnesium) to obtain the pure rare earth metals.

Alloy Formation: The metals are combined with other elements (iron, cobalt, aluminum, etc.) to form advanced alloys.

Examples of applications include:

Nd-Fe-B magnets: Neodymium alloys, derived from carbonates, form the strongest permanent magnets used in EVs and wind turbines.

Aerospace alloys: Yttrium and cerium alloys enhance strength and thermal resistance in jet engines.

Hydrogen storage materials: Mischmetal (a mixture of rare earth metals, originally from carbonates) is used in metal hydride batteries.

This chain of transformations illustrates how essential rare earth carbonates are in bridging natural resources with high-performance alloys.

The influence of rare earth carbonates reaches nearly every high-tech sector because of their role in producing oxides and alloys.

Wind Turbines: Require Nd-Fe-B magnets, which originate from neodymium carbonates.

Electric Vehicles: Depend on rare earth oxides for catalysts and magnets.

Fuel Cells and Hydrogen Storage: Benefit from lanthanum and mischmetal alloys derived from carbonates.

Smartphones and Computers: Use rare earth oxides in screens, phosphors, and polishing agents.

Data Storage: Magnetic alloys made from rare earth metals allow compact, high-capacity storage devices.

Catalytic Converters: Cerium oxides, produced from cerium carbonates, reduce harmful emissions from vehicles.

Water Treatment: Rare earth oxides can capture and remove pollutants.

Jet Engines: Alloys made from yttrium and other rare earths enhance performance at high temperatures.

Lasers and Optics: Rare earth oxides are critical in defense communication and targeting systems.

Rare earth carbonates may never be visible in the final products, but they form the backbone of these industries by enabling the production of the necessary materials.

Compared with other rare earth salts, carbonates offer several clear benefits:

Cleaner Processing: Thermal decomposition produces mainly oxides and CO₂, which is easier to manage than halide or nitrate byproducts.

Lower Corrosion Risk: Unlike chlorides, carbonates are less corrosive, making them safer to handle.

Purification Opportunity: Precipitation methods allow separation of impurities during carbonate formation.

Compatibility: Carbonates can be used as a universal feedstock for producing a wide variety of compounds.

These advantages explain why carbonates remain the most common intermediate stage in rare earth refining and processing.

Despite their importance, rare earth carbonates also face challenges:

Supply Chain Concentration: Most rare earth ores are mined and processed in limited regions, leading to geopolitical concerns.

Environmental Impact: Extracting rare earth ores and processing them into carbonates requires chemicals and energy, raising sustainability issues.

Waste Management: Byproducts such as radioactive elements (thorium, uranium) in some ores complicate carbonate production.

To address these challenges, industries and researchers are exploring:

Recycling: Recovering rare earths from electronic waste to reduce reliance on mining.

Green Chemistry: Developing cleaner processing methods with fewer hazardous byproducts.

Diversified Supply: Establishing new mining and refining facilities in different parts of the world.

As global industries move toward renewable energy, digital technologies, and more efficient manufacturing, the demand for rare earth oxides and alloys will continue to grow. This ensures that rare earth carbonates, as their precursors, will remain central to technological development.

In particular:

The shift to electric mobility will drive demand for neodymium and praseodymium carbonates.

The rise of wind power will boost the need for carbonate-derived magnets.

Advanced electronics and quantum technologies will require increasingly pure rare earth oxides, all stemming from carbonate feedstocks.

The role of rare earth carbonates is therefore not just important today but will be even more critical in the future.

Rare earth carbonates may not be household names, but they are indispensable to modern industry. Acting as the bridge between natural ores and high-tech materials, they enable the production of rare earth oxides and alloys that power everything from clean energy systems to advanced electronics and aerospace technologies.

Their ease of conversion, stability, and ability to serve as universal precursors make them the backbone of rare earth chemistry. While challenges remain in terms of sustainability and supply, innovation in recycling and green processing offers promising solutions.

In the grand picture of advanced materials, rare earth carbonates remind us that even seemingly simple compounds can play a profound role in shaping the technologies of the future.