close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-09-23 Origin: Site

In the modern world, technology relies heavily on advanced materials. From smartphones to renewable energy systems, and from aerospace engines to medical devices, the demand for specialized materials continues to grow. Among these, rare earth compounds play an especially critical role. One group of compounds that has attracted increasing attention in both research and industry is rare earth nitrates. These materials may not be as widely recognized as rare earth oxides or metals, but they are essential intermediates and functional compounds that help power many of today’s most important technologies.

Rare earth nitrates combine the unique properties of rare earth elements with the versatility of nitrates, making them highly valuable in applications ranging from catalysis to electronics. Their importance lies not only in their chemical behavior but also in their ability to support the development of more efficient, sustainable, and high-performance technologies.

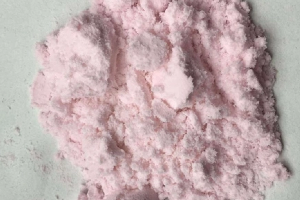

Rare earth nitrates are salts formed when rare earth elements—such as cerium, lanthanum, neodymium, or praseodymium—react with nitric acid. These compounds typically appear as crystalline solids that are soluble in water. Their high solubility, stability, and ability to decompose into oxides upon heating make them useful in a wide range of chemical processes.

Because the term “rare earths” covers 17 elements (the lanthanides, along with scandium and yttrium), rare earth nitrates can vary widely in their specific properties depending on the element involved. For example:

Cerium nitrate is commonly used in catalysts for environmental and industrial processes.

Lanthanum nitrate plays a role in specialty glass and electronics.

Neodymium nitrate can be a precursor for magnetic materials.

This versatility is what makes rare earth nitrates so important in advanced materials development.

The value of rare earth nitrates lies in two main factors: their chemical reactivity and their ease of conversion into other rare earth compounds. Many industries do not use nitrates directly as final products but rather as starting points for producing oxides, fluorides, or other rare earth derivatives. However, in specific applications, the nitrates themselves are highly effective.

For instance, in catalysis, the nitrate form provides excellent dispersion on support materials, allowing rare earth ions to interact efficiently with reactants. In electronics, their solubility makes them suitable for preparing thin films and coatings, which are critical in devices that demand precision and uniformity.

In short, rare earth nitrates act as both functional chemicals and transitional materials that bridge basic raw rare earths with advanced technologies.

Catalysts are materials that accelerate chemical reactions without being consumed in the process. They are fundamental in industries such as energy, petrochemicals, and environmental management. Rare earth nitrates are particularly valued in this field for several reasons:

One of the most prominent uses of rare earth nitrates is in automotive catalytic converters. These devices reduce harmful emissions from vehicles by converting carbon monoxide, nitrogen oxides, and hydrocarbons into less harmful gases. Cerium nitrate is especially important here, as cerium oxide derived from it can store and release oxygen, enhancing the efficiency of the catalyst.

Rare earth nitrates are also used in refining and petrochemical industries. For example, they help in the catalytic cracking of hydrocarbons, which is a key step in producing fuels and valuable chemicals from crude oil. The presence of rare earth elements improves catalyst stability and selectivity, enabling more efficient processes.

In addition to fuel and chemical production, rare earth nitrates are applied in environmental protection. Catalysts prepared from these nitrates are used in processes such as wastewater treatment, flue gas cleaning, and renewable energy production. Their ability to enhance oxidation and reduction reactions makes them vital for tackling modern environmental challenges.

The electronics industry is another area where rare earth nitrates play an important role. As devices become smaller, more powerful, and more energy-efficient, the demand for precise and reliable materials increases. Rare earth nitrates contribute to this in several ways:

Because of their solubility, rare earth nitrates are commonly used in solution-based deposition methods for creating thin films. These films are essential in semiconductors, sensors, and optical devices. For example, coatings made from lanthanum or cerium nitrates can enhance the performance of capacitors or improve the durability of display technologies.

Certain rare earth nitrates, like neodymium nitrate, are precursors for high-performance magnets. These magnets are critical in electronics ranging from hard drives to wind turbine generators. The ability to produce high-purity rare earth compounds from nitrates ensures consistent quality in these advanced magnetic materials.

Lanthanum and cerium nitrates are also used in the production of specialty glass. Such glass is employed in camera lenses, fiber optics, and laser systems. These nitrates help improve transparency, reduce UV transmission, and enhance other optical properties.

Rare earth nitrates are widely favored in advanced materials research and industry because they offer several advantages:

High Purity and Consistency – Their production processes allow for highly controlled purity levels, which is essential in electronics and catalysts.

Ease of Processing – Being water-soluble, they are easy to handle in chemical synthesis and thin-film production.

Versatility – They serve as both active materials and intermediates for other compounds.

Performance Enhancement – In catalysts and electronic devices, they improve efficiency, stability, and durability.

Despite their importance, rare earth nitrates also present some challenges. One major concern is the supply of rare earth elements themselves. Mining and refining rare earths can be resource-intensive and environmentally challenging. The concentration of rare earth resources in specific regions also creates supply chain risks.

In addition, handling nitrates requires caution due to their potential to release nitrogen oxides during decomposition. Industries using these materials must ensure proper environmental and safety standards.

Research is ongoing to address these issues, including recycling rare earths from electronic waste and improving extraction technologies to reduce environmental impacts.

The future of rare earth nitrates is closely tied to the growth of high-tech and sustainable industries. As demand for clean energy, efficient electronics, and advanced catalysts increases, the need for rare earth nitrates is expected to rise. Several emerging areas highlight this trend:

Renewable Energy – Rare earth nitrates will continue to support the development of catalysts for hydrogen production and fuel cells.

Next-Generation Electronics – With the rise of 5G, electric vehicles, and smart devices, the demand for rare earth-based materials, including nitrates, will grow.

Green Manufacturing – Research into environmentally friendly processes will create new opportunities for rare earth nitrates in sustainable technologies.

The combination of versatility and functionality ensures that rare earth nitrates will remain a cornerstone in the world of advanced materials.

Rare earth nitrates may not always be in the spotlight, but their role in catalysts and electronics makes them indispensable in modern technology. By combining efficiency, versatility, and high performance, they enable industries to create cleaner energy systems, more powerful electronic devices, and more sustainable manufacturing processes.

From enhancing automotive catalytic converters to enabling thin-film electronics, rare earth nitrates demonstrate how critical advanced materials are in shaping the future. As industries continue to innovate, these compounds will unlock even greater potential, proving that sometimes the most essential materials are the ones working quietly behind the scenes.